Products

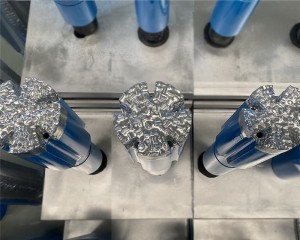

Summus efficientiam Downhole Milling Tools

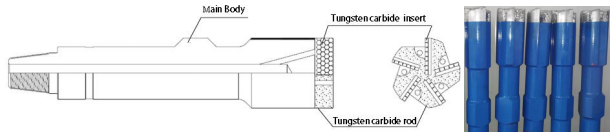

Product Material

Accipe plana calceamenti molendini in exemplum:

Praecipuum corpus summus exsecutionis offensionis ferrum adoptat (4145H) ut lenis et efficax operatio sub variis pressionis exercendis et in gyratorio situ velocitatis curet. Interea rogamus altam tungsten carbide meterial ad consequi celeriter milling. Stabilizer et extra alam pro mola junk et molendini cerei pro necessitate designari potest.

Wolframium carbide inserta

·Superloy

Bonus fillulus pro pepone, chorda et lychnus molendinorum.

Bene dorsum pro mola junk.

Amplis magnitudinum praesto.

Asperrima.

· Metal Muncher

Molendina citius quam instrumenta molendi conventionales.

Reduces requiratur EXERCITATIO pressura dum milling.

Folia leviora secant sine labris ad obstantia pendere.

Obstantia pari magnitudine.

Secans metallum pro molere est.

· Opti-cut

Admovit minor.

Velocius ROP.

Longior vita.

Inferius pressura et torque requisita.

16 Puncta secans, et 8 oras pro singulis dromonis.

Product Category

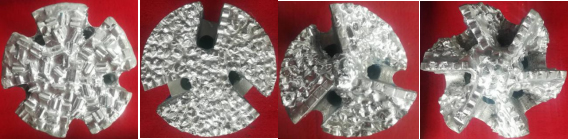

Concava / Flat / Blade Bottom junk molendini

Usus est ad frenum, conum, diametrum METIOR, dentes luctandi, fistulam lavandi, instrumentum iuncturam exercendi, accessiones profundae bene sentinae, fasciculus, aqua distributor et alia instrumenta longiora exercendis.

Petrozhr junk molendinum variis conformationibus et geometriis praesto sunt. Molendini nostri progressus machinalis et periti welder efficere ut structuram constantem et durabilem in omni junk molendini secando.

Tab. I Flat / Concave / Lamina imo junk molendini parametri

| Borehole Dia. Molendinum ornare risus OD commendatur Longitudo Screw Thread (mm) (mm) | PN Flat | PN concavum | PN Bladed |

| 95.2- 101.6 89 2-3/8REG 250 | JM089FX | JM089CX | JM089BX |

| 107.9- 114.3 97 2-3/8REG 250 | JM097FX | JM097CX | JM097BX |

| 117.5- 127 110 2-7/8REG 250 | JM110FX | JM110CX | JM110BX |

| 130- 139.7 121 2-7/8REG 250 | JM121FX | JM121CX | JM121BX |

| 142.9- 152.4 130 2-7/8REG 250 | JM130FX | JM130CX | JM130BX |

| 155.6- 165. 1 140 3- 1/2REG 250 | JM140FX | JM140CX | JM140BX |

| 168- 187.3 156 3- 1/2REG 250 | JM156FX | JM156CX | JM156BX |

| 190.5-209.5 178 3- 1/2REG 250 | JM178FX | JM178CX | JM178BX |

| 212.7-241.3 200 4- 1/2REG 250 | JM200FX | JM200CX | JM200BX |

| 244.5-269.9 232 4- 1/2REG 250 | JM232FX | JM232CX | JM232BX |

| 273-295.3 257 6-5/8REG 250 | JM257FX | JM257CX | JM257BX |

| 298.5-317.5 279 6-5/8REG 250 | JM279FX | JM279CX | JM279BX |

| 320.6-346. 1 295 6-5/8REG 250 | JM295FX | JM295CX | JM295BX |

| 349.3-406.4 330 6-5/8REG 250 | JM330FX | JM330CX | JM330BX |

| 406.4-444.5 381 6-5/8REG 250 | JM381FX | JM381CX | JM381BX |

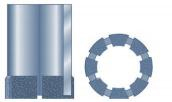

Calceamentum gyratorius

Calceamentum gyratorium carbidam intra cylindrum materialem adhibet, ut circumferentialiter pisces inaequaliter secet verticem, et paulatim resarciat verticem piscium laesum in circulum, ut Tubing, corpus armamentum, etc.

[Nota: Quia dens molaris interior diametri calcei rotati est magnus, e converso torques magnus est, ita humilis pressionis et tardus gyrationis modus adhibendus est in usu calcei gyratorii. In genere, EXERCITATIO pressionis X KN non excedat et celeritas gyratoria 50 r/min non excedat.]

Typus A

Metallum incide, caementum et formatio.

Secans in OD et fundum.

Typus B

Metallum secans ubi alvi parva est.

Secans in ID et fundum.

Typus C

Secta formatio.

Secans in OD et fundum.

Typus D

Incidere formationem et pisces simul.

Secans in ID, OD et fundum.

Tab.2 Gyratorius calceamentum parametri

| Casing / Wellbore Diae. | Gyratorius calceamentum OD (mm) | Calceamentum gyratorium Longitudo (mm) | Commendatur stupra Thread | PN Calceamentum gyratorius | |

| 4in | 101.6mm | 95 400 | FJWP | TXX095 | |

| 5- 1/2in | 139.7mm | 114 500 | FJWP | TXX114 | |

| 5-3/8in | 146.05mm | 118 500 | FJWP | TXX118 | |

| 6-5/8in | 168.28mm | 136 425 | FJWP | TXX135 | |

| 7in | 177.8mm | 152 450 | FJWP | TXX152 | |

| 7-5/8in | 193.68mm | 160 450 | FJWP | TXX160 | |

| 8-5/8in | 219. 1mm | 185 550 | FJWP | TXX185 | |

| 12- 1/4in 311. 15mm | 203 450 | FJWP | TXX203 | ||

| 15-5/8in 396.88mm | 298 450 | FJWP | TXX298 | ||

| 20in | 508mm | 406 450 | FJWP | TXX406 | |

Taper Mill

Molendini cerei limites ex limitationibus, concidit armamentis et sectionibus lineis et deburr lorarii fenestris et casing. Molendini cerei humilis, cum suis parvis, diametro ingreditur thecam collapsam et liner. Deinde margines leviter spirales reamer ad sub sectione ad plenam molendini auferendam. molendinum diametri.

Mola cerea in corpore conico et carbide tungsteno constat. Clypeus corporis 30 gradus est, pyramis alis informibus, et superficies carbidi duriori vel inlinitur.

Tab.3 molendini Taper parametri

| Borehole Dia. Taper molendinum OD Commendatur Longitudo (mm) (mm)Screw Thread(mm) | P.N. Taper molendinum | ||

| 95- 101.6 | 89 | 2-3/8REG 300 | XZ089 |

| 107.9- 114.3 97 2-3/8REG 300 | XZ097 | ||

| 117.5- 127.0 110 2-7/8REG 300 | XZ110 | ||

| 130- 139.7 121 2-7/8REG 300 | XZ121 | ||

| 142.9- 152.4 130 2-7/8REG 300 | XZ130 | ||

| 155.6- 165. 1 140 3- 1/2REG 300 | XZ140 | ||

| 168- 187.3 156 3- 1/2REG 300 | XZ156 | ||

| 190.5-209.5 178 3- 1/2REG 300 | XZ178 | ||

| 212.7-241.3 200 4- 1/2REG 300 | XZ200 | ||

| 244.5-269.9 232 6-5/8REG 350 | XZ232 | ||

| 273-295.3 257 6-5/8REG 350 | XZ257 | ||

| 298.5-317.5 279 6-5/8REG 350 | XZ279 | ||

| 320.6-346. 1 295 6-5/8REG 350 | XZ295 | ||

| 349.3-406.4 330 6-5/8REG 350 | XZ330 | ||

| 406.4-444.5 381 6-5/8REG 350 | XZ381 | ||

PEPO String Mill

PEPO chorda calceus unus est instrumentorum molendi in operatione sidetracking. Ponitur ad reficiendas venas, reamantis et aperiendas vias. Solet uti statim post fenestras aperturas. Molendinarium (aream laborantem) molendini PEponis contactus muri boreholi, et finis cuiuslibet extremitatis ut pyramis designatus est. Cum fenestra aperitur, molendinum peponis a summo fenestra extendere potest et scalas et lappas in tibia parieti in sectione initiali relictas removere.

Tab.4 PEPO filum molendini parametri

| Borehole Dia. Screw (mm/in) Thread | Area opus OD (mm/in ) | Area Longitudo (mm/in) | Totul Longitudo (mm/in) | PN |

| 139.7 (5- 1/2) NC 26 112 (4-7/ 16) 600 (23-5/8) | 1130 (44). | XGMX112 | ||

| 139.7 (5- 1/2) NC 26 116 (4-9/ 16) 600 (23-5/8) | 1130 (44). | XGMX116 | ||

| 139.7 (5- 1/2) NC 26 118 (4-5/8) 600 (23-5/8) | 1130 (44). | XGMX118 | ||

| 139.7 (5- 1/2) NC 31 120 (4-3/4) 600 (23-5/8) | 1280 (50). | XGMX120 | ||

| 146.0 (5-3/4) NC 31 124 (4-7/8) 600 (23-5/8) | 1280 (50). | XGMX124 | ||

| 168.3 (6-5/8) NC XXXI 142 (5-9/ 16) 600 (23-5/8) | 1280 (50). | XGMX142 | ||

| 177.8 (7) NC XXXI 151 (5- 15/ 16) 600 (23-5/8) | 1280 (50). | XGMX151 | ||

Gubernator molendini

Molendinum gubernatori destinatur ad armaturam molendam, calceum rotarium vel magnum ID Tubing. Laminae secandae cum materia carbide tungsten ornatae alto genere faciunt molendinum gubernator Petrozhr ad acumen festinanter cum minimis induendis consequi potuit. Minima et crispa strages secans facile est removere. Et gubernator finis adhibetur ad stabiliendum in ID rei, quod molitum est.

Tab.5 Molendini nauclerus parametri

| Borehole Diae. (mm) | Screw Thread | Area opus OD (mm) | Longitudo lamina secans (mm) | Gubernator regio Longitudo (mm) | PN |

| 153 2 3/8REG | 130 200 | 45 | LYMX130 | ||

| 165 2 3/8REG | 140 200 | 45 | LYMX140 | ||

| 187 3 1/2REG | 156 200 | 55 | LYMX156 | ||

| 210 4 1/2REG | 178 200 | 55 | LYMX178 | ||

| 241 4 1/2REG | 200 200 | 55 | LYMX200 | ||

| 270 4 1/2REG | 232 200 | 55 | LYMX232 | ||

| 295 6 5/8REG | 257 250 | 55 | LYMX257 | ||

| 317 6 5/8REG | 279 250 | 55 | LYMX279 | ||

| 346 6 5/8REG | 295 300 | 55 | LYMX295 | ||

| 406 6 5/8REG | 330 300 | 55 | LYMX330 | ||

| 445 6 5/8REG | 331 300 | 55 | LYMX331 | ||

Tungsten carbide application chart

| Commendatur application | Superloy | Opti-cut | Metallum muncher | Metallum muncher cum Superloy |

| Washover aperta foraminis | √ | √ | ||

| Washover terebro pipe | √ | |||

| Washover calculo sarcina | √ | √ | ||

| Washover liner absumpto | √ | |||

| Washover packer | √ | |||

| Poilt milling | √ | |||

| Solve Junk milling | √ | √ | ||

| Packer stationarius vel fistula vel tubingjunk milling | √ | |||

| PEPO Milling | √ | |||

| Filum milling | √ |

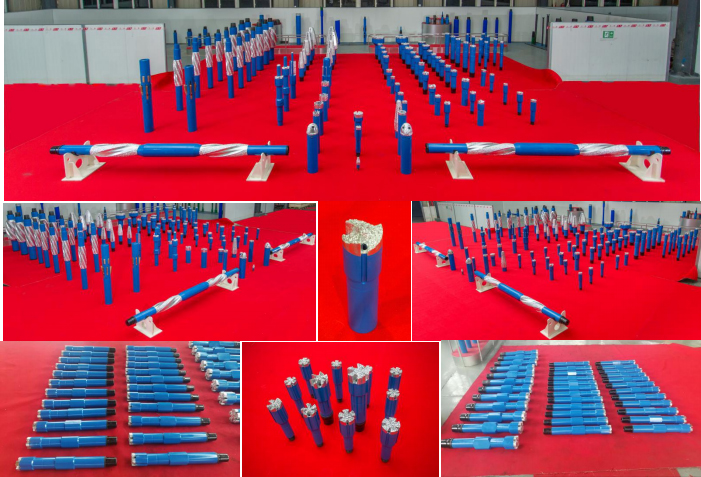

Pisces Item Pictures

Locus 703 Aedificium B, Groenlandiae centrum, Hi-tech evolutionis zona Xi'an, China

Locus 703 Aedificium B, Groenlandiae centrum, Hi-tech evolutionis zona Xi'an, China 86-13609153141

86-13609153141